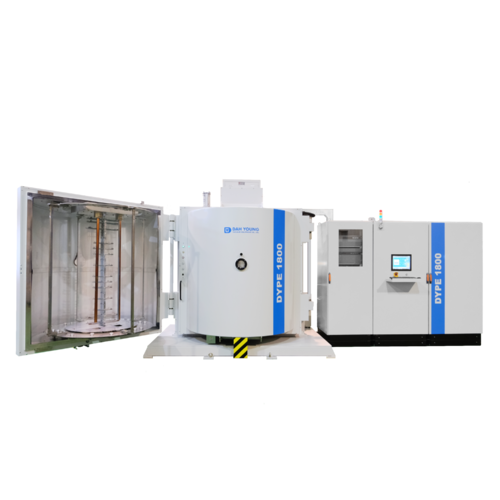

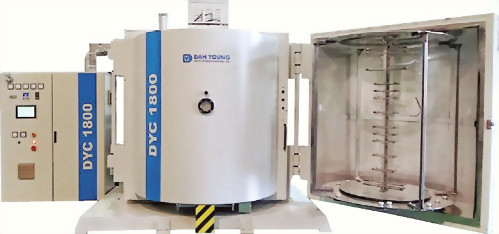

Plasma cleaning machine

Although the plasma cleaning process has been performed for many years, the application has been expanded in recent years due to changes in the industrial structure. Plasma Cleaning uses high temperature or strong electromagnetic fields to dissociate substances, release ultraviolet light, and destroy the organic bonds of grease or ointment on the sample surface. When the reaction gas introduced into the vacuum chamber cavity ionizes to produce positive and negative ions, free radicals and electrons, these particles will combine with the bond of oil stains to form gaseous compounds such as CO2 and H2O, which are then pumped out of the cavity.

The advantages of plasma cleaning over traditional solvent cleaning are that the cleaned samples do not require baking, the process will not cause environmental pollution, and the plasma cleaning machine is simple to operate, which can greatly reduce the labor and material costs required compared to traditional solvent cleaning with excellent results.

- The plasma system is stable and the electrode design has a uniform plasma distribution to clean the material thoroughly without any untreated facets.

- The highly flexible gas supply system improves the cleaning effect.

- Streamlined operation interface, and real-time display of equipment system status, make the equipment operation and process clear at a glance.

- The design of automatic feeding and discharging system reduces labor costs.

Oxidation and reduction of metal surface, surface treatment of glass and polymer materials, pretreatment of coating, etc.

Take the automotive lighting industry for example:

Old process:

New process:

Plasma cleaning effect

Comparison table of Manual Solvent Cleaning and Plasma Cleaning Machine