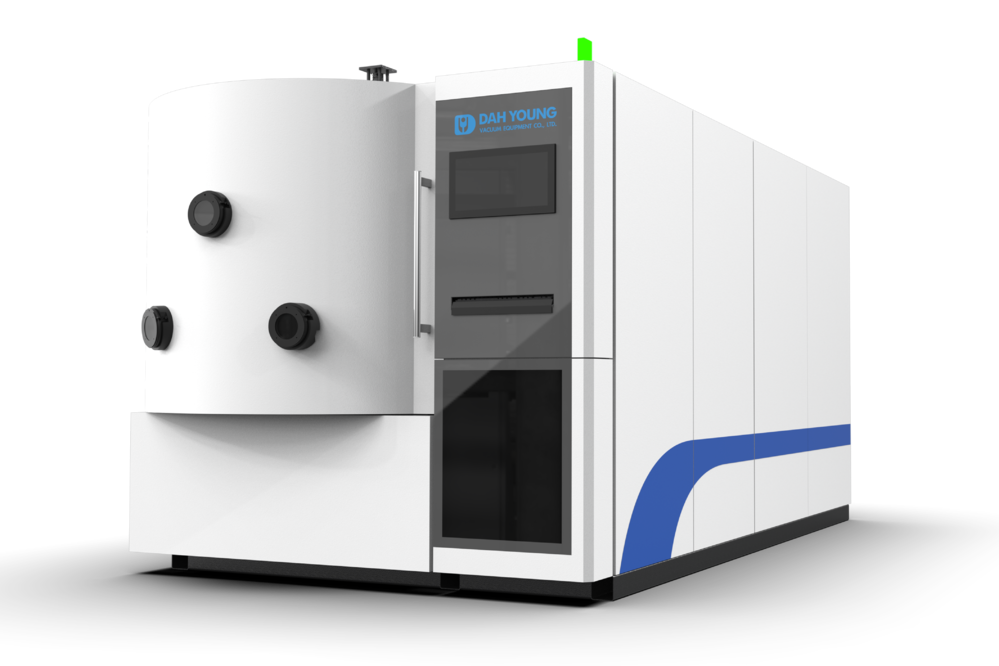

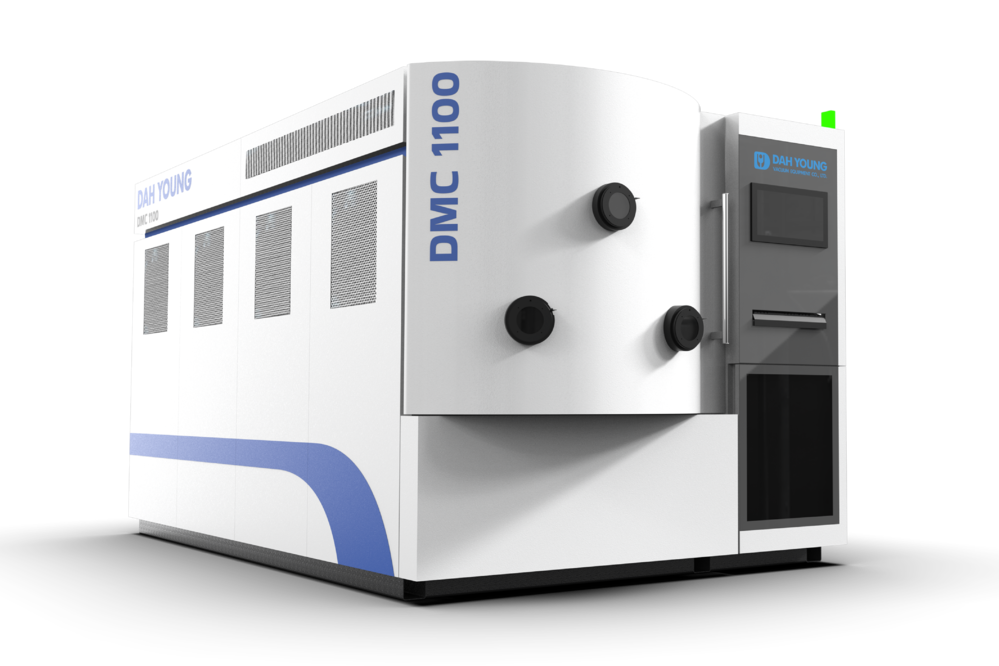

DMC Coating Machine

DMC|High-Efficiency, Mass-Production Oriented E-beam Evaporation System

- The Classic Solution for Precision Optical Coating

In the field of optical coating, Electron Beam (E-beam) Evaporation remains the cornerstone for achieving high deposition rates and versatile film design. However, modern optical applications demand rigorous standards for yield, throughput, and thickness precision. Equipment stability and technical integration have become the ultimate competitive advantages.

Building on decades of practical experience and R&D expertise, Dah Young Vacuum presents the DMC (Dah Young Multi-Functional Coater). More than just a vacuum system, the DMC is a comprehensive process platform integrating Dah Young’s proprietary core technologies. Designed for a wide spectrum of applications—from decorative and optoelectronic to high-precision optics—it provides a stable, high-efficiency, and highly autonomous solution for vacuum evaporation.

- Stable Evaporation Architecture Ensuring Consistent Film Quality

DMC adopts an optimized high-energy E-beam evaporation structural design. Through precise beam current control and crucible configuration, the coating material can rapidly reach the ideal evaporation temperature, achieving fast and uniform coating effects.

This design not only significantly improves deposition efficiency but also ensures that thickness uniformity and optical performance during large-area coating remain consistent across different batches, making it particularly suitable for continuous production applications with high throughput requirements.

Combining an advanced vacuum pumping system with chamber flow field design, DMC can maintain a stable high-vacuum environment during the process, effectively reducing background gas interference and ensuring that optical film layers possess excellent purity and adhesion.

- Modular Chamber Configuration, Adapting to Diverse Capacity and Process Demands

The DMC series features high modular design flexibility. Based on different capacity planning and facility space, it provides the industry's most complete selection of standardized chamber sizes (800, 1100, 1350, 1550, 1800, 2050).

Whether for small-batch diversified R&D needs or system configurations for large-size substrates and large-scale mass production, DMC can assist customers in achieving optimal equipment investment efficiency and capacity expansion planning at different development stages through flexible size options.

Through the modular design concept, DMC can be equipped with optional heating systems, ion-assist modules, and process monitoring components according to actual application needs, further enhancing film quality, process flexibility, and overall equipment adaptability.

- Self-Developed Key Cores, Precisely Mastering Complex Multi-Layer Film Processes

To meet the extreme requirements of precision optical coating for "process controllability" and "spectral accuracy," DMC equipment fully introduces key auxiliary systems self-developed by Dah Young Vacuum, achieving high integration of software and hardware:

- Dah Young Self-developed Optical Monitoring System (Proprietary Optical Monitoring System): DMC is equipped with Dah Young’s self-developed optical monitoring technology, deeply optimized for evaporation process characteristics. The system can instantly and accurately detect optical changes in film deposition thickness. Through exclusive algorithms and seamless connection with the equipment control end, it achieves millisecond-level rapid corrections. This ensures that every layer of film thickness precisely hits the design value, effectively solving the film thickness drift problem in long processes and significantly improving yield.

- Full Series of Self-made High-Performance Ion Sources (18 / 24 / 27 cm Ion Sources): Aiming at different chamber sizes and process requirements, DMC is configured with Dah Young’s independently developed high-performance ion sources, providing various specifications such as 18 cm, 24 cm, and 27 cm.

- Optimized Matching: Self-made ion sources can achieve optimal matching with the chamber geometry, ensuring uniform coverage of the ion beam flow field.

- Enhancing Film Quality: Powerful Ion-Assisted Deposition (IAD) capability significantly improves film density and environmental tolerance, providing evaporated films with excellent mechanical strength and environmental stability, even obtaining superior quality in low-temperature processes.

This "In-house Core Technology" strategy not only enhances the overall performance of the equipment but also enables Dah Young to provide customers with more immediate and in-depth technical support and process optimization services.

- An E-beam Evaporation Platform Born for High-Efficiency Production

Compared to traditional assembled equipment, DMC focuses more on system integration, process stability, and maintenance convenience.

Its design philosophy centers on the "smooth transition from development to mass production," assisting customers in shortening machine adjustment time, reducing process variation risks, and maintaining high utilization rates and excellent yield performance in actual production environments.

DMC is particularly suitable for applications in:

- Precision optical lenses and filters

- Various reflective films and Anti-reflective coatings

- Optoelectronic sensing components and industrial coatings

- Decorative coatings and consumer electronics exterior parts

-

Flexible Configuration: Available in six standardized specifications: 800, 1100, 1350, 1550, 1800, and 2050 mm.

- Comprehensive Range: From small-batch R&D samples to large-size substrates or ultra-large-scale production lines, corresponding models are available to meet expansion needs at different stages.

-

Technology: Equipped with Dah Young’s self-developed optical monitoring software and hardware, specifically optimized for the evaporation process.

- Precision Control: Featuring millisecond-level rapid correction capability to ensure every layer thickness in multi-layer film processes precisely hits the design target

- Improvement: Effectively resolves film thickness drift issues in long processes, significantly enhancing spectral accuracy and production yield.

-

Specifications: Configured with Dah Young’s self-produced 18cm, 24cm, or 27cm ion sources based on chamber size.

- Optimal Matching: The ion source and chamber geometry are perfectly matched to ensure uniform coverage of the flow field.

- Superior Film Quality: Powerful Ion-Assisted Deposition (IAD) capabilities significantly improve film density, mechanical strength, and environmental tolerance, performing excellently even in low-temperature processes.

- High-Efficiency Deposition: Optimized high-energy E-beam system to achieve rapid and uniform coating effects.

- Superior Film Quality: Powerful Ion-Assisted Deposition (IAD) capabilities significantly improve film density, mechanical strength, and environmental tolerance, performing excellently even in low-temperature processes.

- Software & Hardware Integration: Seamlessly connects self-developed core components (OMS, Ion Source) with the equipment control system.

- High Utilization Rate: The design focuses on operational stability and maintenance convenience, assisting customers in shortening learning curves and machine setup times to achieve high-efficiency and stable production output.

With its comprehensive chamber range of 800–2050 mm and the integration advantages of high-precision Optical Monitoring (OMS) and powerful Ion Sources (IAD), the DMC series widely covers diverse applications from semiconductors and LEDs to high-end precision optics:

1. Semiconductor & LED Optoelectronics

The high-directionality evaporation characteristics and low-temperature ion-assist capability of the DMC are particularly suitable for compound semiconductors, various LED processes, and MEMS.

- LED / Mini & Micro LED

- High-Reflective Structures: Fabrication of Distributed Bragg Reflectors (DBR) or high-reflectivity metal mirrors (Ag, Al) to significantly enhance the Light Extraction Efficiency (LEE) of flip-chip or vertical LEDs.

- Transparent Conductive Oxides (TCO): Deposition of high-quality ITO films with both high transmittance and low sheet resistance to optimize current spreading performance.

- Electrodes & Ohmic Contacts: Metal deposition for p/n electrodes (e.g., Ni/Au, Ti/Pt/Au, Cr/Pt/Au).

2. Precision Optics

For imaging and projection components with strict spectral requirements, the DMC’s optical monitoring system ensures the precision of complex film stacks.

- Applications: DSLR/Digital camera lenses, microscope/telescope lenses, projector optical engine components, laser optical components.

- Common Coatings: Broadband Anti-Reflective (BBAR) coatings, High-Reflectivity (HR) films, Beamsplitters, and Cut-off Filters.

3. Automotive Optics & LiDAR

Utilizing the low-temperature dense film formation of Dah Young’s in-house ion sources (IAD) to pass rigorous automotive-grade environmental reliability tests (high temperature/humidity, abrasion resistance).

- Applications: Automotive lenses, Head-Up Display (HUD) mirrors, LiDAR protection windows, automotive lighting optical lenses.

-

Common Coatings: IR Pass/Cut filters, high-durability AR coatings, and Cold Mirrors.

4. Consumer Electronics

Utilizing large-size chambers (1550/1800/2050) to achieve mass production, meeting the massive capacity demands of smartphones and wearable devices.

- Applications: Mobile lens protectors, tablet/laptop display components, smartwatch windows.

- Common Coatings: Anti-Reflective (AR) coatings, Anti-Fingerprint/Anti-Smudge (AF/AS) coatings, Infrared Cut-off Filters (IRCF).

5. Bio-medical & Sensing

Combining optical monitoring and ion-source assistance to produce optical filters with high signal-to-noise ratios and high stability.

- Applications: Facial recognition sensors (3D Sensing), ambient light sensors, endoscope lenses, biomedical testing filters.

- Common Coatings: Narrow Bandpass Filters and Dichroic Mirrors.

6. Eyewear

For resin and plastic substrates, the DMC’s low-temperature ion-assist process prevents substrate deformation while ensuring film hardness and adhesion.

- Applications: Prescription lenses, sunglasses, sports goggles (ski/diving masks), safety eyewear.

- Common Coatings: Anti-blue light coatings, Mirror coatings, and Anti-reflective (AR) enhancement coatings.

7. Decorative & Functional

Utilizing the high loading capacity of large chambers to perform high-efficiency decorative metallization, achieving both a metallic texture and signal transparency.

- Applications: Luxury packaging, cosmetic containers, watch components, 3C product housings.

- Common Coatings: NCVM (Non-Conductive Vacuum Metallization), metallic texture coatings, and gradient color coatings.