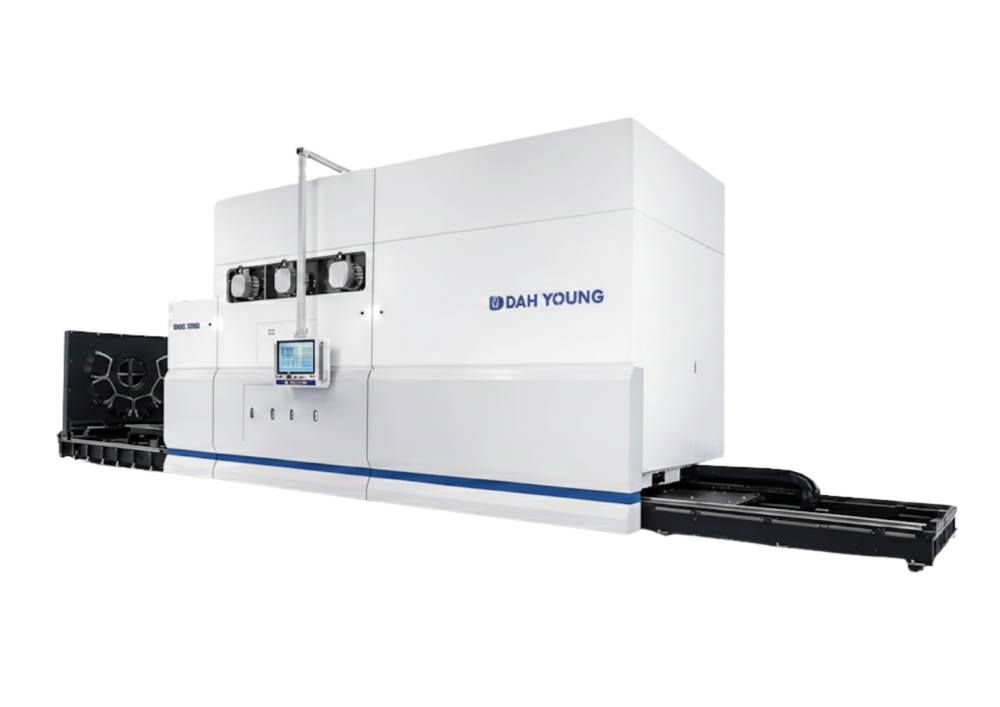

R2R Vacuum Coating Machine

- High-Efficiency Continuous R2R Vacuum Coating Machine

Dah Young's R2R (Roll-to-Roll) vacuum coating machine is designed for high-efficiency continuous processing of flexible substrates, including plastic films, metal foils, textiles, and footwear fabrics. The system integrates magnetron sputtering, plasma cleaning, PECVD, and high-energy plasma-assisted processes, delivering both high-throughput production capability and excellent film uniformity. It is widely applied in optoelectronics, flexible electronics, new energy, and functional textile industries.

- 2000 mm Width Coating with High-Uniformity Process Control

DMRC series supports wide-width roll-to-roll coating up to 2000 mm and incorporates advanced German plasma monitoring technology to track plasma conditions in real time. This enables coating uniformity across the full 2000 mm width to be stably controlled within ±5%, ensuring consistent mass-production quality while effectively resolving edge effects and batch variations commonly encountered in conventional wide-width R2R processes.

- High-Precision Tension Control and Versatile Flexible Substrate Compatibility

For process stability, Dah Young's high-precision tension control system supports ultra-thin to medium-thickness films ranging from 6 μm to 50 μm. Even under high-speed operation and wide-width conditions, it maintains stable web handling and precise deposition. The system is also suitable for structurally complex textiles and footwear fabrics, meeting the stringent process control requirements of diverse flexible materials.

- HiPIMS High-Adhesion Coating Technology for Advanced Functional Applications

For applications requiring high adhesion, high reliability, and superior interface quality, the system can be equipped with optional HiPIMS (High Power Impulse Magnetron Sputtering) power technology. The highly ionized metal plasma significantly enhances film density, adhesion, and durability, making it ideal for functional coatings subjected to high stress, wear resistance, or downstream processing.

- Building Long-Term Competitive Advantage for Advanced Material Mass Production

Driven by the continued growth of 5G, electric vehicles, wearable devices, and functional textile markets, Dah Young combines a 2000 mm wide-width platform, German real-time plasma monitoring, advanced HiPIMS sputtering technology, and ultra-thin film tension control to deliver an R2R vacuum coating manufacturing platform with long-term production stability, process upgrade flexibility, and strong market competitiveness.

- Integrated deposition of organic and inorganic layers in a single process

- The process capabilities beyond traditional atmospheric coatings

- Achieving a uniform and controllable film thickness for ultra-thin film layers.

- The film layer exhibits high purity, minimal impurities, a smooth surface, and a low occurrence of pinholes.

- Surface performance enhancements (anti-scratch, high light transmittance, hydrophilic/hydrophobic properties, etc.)

- Equipped with planar and rotary target holders, users can select from various target types.

- This system allows for the simultaneous coating of multiple sources, including metals, alloys, and dielectric materials.

- A separate chamber can be utilized for various sputtering or Plasma-Enhanced Chemical Vapor Deposition (PECVD) coating methods at different pressures.

RFID, 5G Devices, PCB, Electric Vehicles, Touch Screens, Automotive Displays, E-Paper, Polarizer, Smart Glass, ITO films, Flexible solar cell, Perovskite solar cell, Barrier film, and Biological reagents.