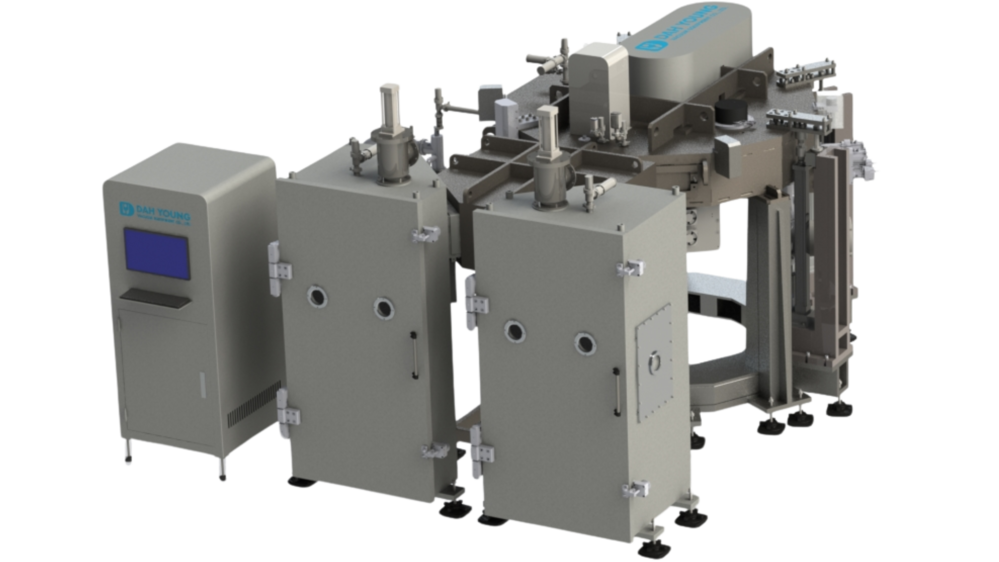

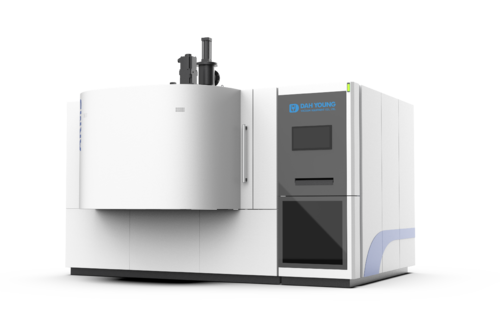

ORBIS Coating Machine

- ORBIS Series: High-Rate, Multi-Layer Optical Coating Solutions for Semiconductor Optics

To meet the growing demand for precision optical coatings in the semiconductor industry, Dah Young Vacuum has developed the next-generation ORBIS series (Optical Rotation Beam Ion Sputtering) — a horizontal reactive ion sputtering system. This system enhances coating process stability and accuracy, making it especially suited for high-quality, multi-layer coatings on advanced semiconductor optical components.

The ORBIS system separates the reactive gas activation zone from the sputtering area and incorporates a high-speed rotating chamber. This design ensures that the substrate sequentially passes through the target and plasma zones, enabling fast, precise switching between metal and oxide film deposition. The system offers three core advantages:

- Low-temperature sputtering: ideal for heat-sensitive semiconductor substrates.

- High-efficiency ICP (Inductively Coupled Plasma) ion source: improving plasma activity and film quality.

- Significant particle suppression: ensuring clean thin films.

- Precision Energy Control & Step Coverage for High-Accuracy Planar Optical Film Stacks

The ORBIS system features a horizontal layout with separate zones for sputtering targets and plasma generation. Inert gas is introduced to the target zone, while a mixed reactive gas is activated in the plasma zone. This configuration minimizes unwanted target reactions and poisoning effects, thereby improving overall process stability.

With excellent film thickness uniformity, precise molecular energy control, and strong step coverage performance, the system enables reliable stacking of complex, high-precision optical films—particularly beneficial for microstructured semiconductor devices.

Typical applications include anti-reflective coatings for high-resolution CMOS and CCD image sensors, high- and low-reflective coatings for VCSELs and other laser emitters, as well as narrow bandpass and edge filters used in optical communication modules. These applications demand highly uniform and optically functional thin films, and the ORBIS system delivers exceptional performance to meet these stringent requirements.

- High Deposition Rate and Process Stability for Scalable Semiconductor Optical Manufacturing

The ORBIS system is specifically designed to minimize particle contamination during deposition. By using a bottom-up ion bombardment approach, it further reduces particle generation and ensures a consistently clean, high-quality film surface.

The platform supports superlattice coating structures with over 50 layers, demonstrating outstanding multi-layer stacking capability. Its chamber is equipped with multi-point target configuration for both single and dual-target setups, offering flexibility for a wide range of metal materials and coating recipes.

Moreover, the system mixes and activates process gases before they enter the chamber, which significantly improves reaction efficiency and overcomes the instability issues typically seen in reactive sputtering.

With its three key attributes — high deposition rate, excellent film quality, and robust process stability — the ORBIS platform provides powerful support for advanced semiconductor optical applications in high-volume manufacturing.

- Fully automatic control (IPC & PLC), capable of producing high-quality optical films and composite multi-layer optical films.

- Fully automatic coating software with easy parameter setting. It can directly load optical design files and simulate the completion of the spectrum before the deposition process. The machine can also be equipped with remote connection capabilities to monitor the process in real-time.

- The horizontal activation reaction sputtering target adopts an adjustable design, which can be customized according to customer needs. The distance between targets can be fine-tuned, and an alloy metal partition is installed in the middle to completely prevent target poisoning.

- Complete process parameter files and historical records are available for users to read historical data for analysis and optimization, with the ability to set the recording interval in seconds.

- The machine is equipped with multiple emergency stop and shutdown devices, enhancing the safety of personnel during operation. It can also be equipped with a convenient transport system for loading and unloading.

- Automated robotic arms are used for wafer loading and unloading, enabling continuous large-batch production and 24-hour uninterrupted operation.

- High-resolution CMOS image sensor modules

- Vertical-Cavity Surface-Emitting Laser (VCSEL) modules

- Smart Surveillance Cameras

- Chip-scale optical filters

- Optical Coatings for LED Devices

- Image Sensor