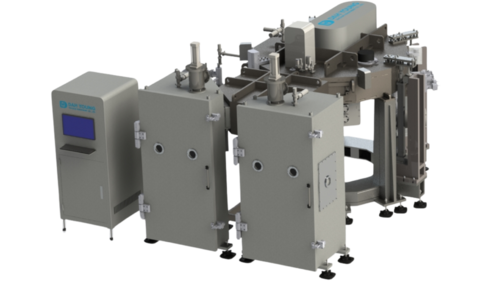

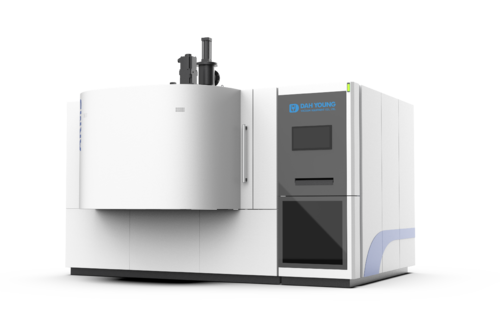

DYSP Sputtering Coating Machine

DYSP|A Production-Oriented Optical Sputtering Coating System

- A Reliable Solution for Mainstream Optical Coating Applications

In advanced optical coating applications, performance limits are not the only focus. Long-term operational stability, yield consistency, and process reproducibility are equally critical for volume manufacturing.

Leveraging decades of experience in optical evaporation and sputtering equipment integration, Dah Young Vacuum introduces the DYPS Optical Sputtering Coating System (Dah Young Precision Sputtering System)—a stable, reliable, and highly flexible platform designed specifically for mainstream optical film stacks and mass-production requirements.

By integrating proven magnetron sputtering technology into optical coating processes, DYPS delivers high film quality while maintaining excellent process stability, enabling customers to establish scalable, long-term production foundations. It represents a practical and effective solution for transitioning optical sputtering processes into stable mass production.

- Stable Sputtering Architecture for Consistent Optical Film Quality

DYPS features a field-proven magnetron sputtering architecture. Through optimized target configuration, substrate rotation mechanisms, and gas flow control, the coating process remains highly stable throughout operation.

This design effectively minimizes process fluctuations, ensuring uniform film thickness and consistent optical performance across batches—making DYPS particularly suitable for long-duration, continuous production environments.

The inherently high kinetic energy of sputtered particles produces dense film structures, enhancing durability and environmental stability. This meets the stringent reliability and consistency requirements of mass-produced optical components.

- Flexible Target Configuration Supporting Diverse Optical Film Designs

The DYPS chamber is designed with flexible multi-target configurations, accommodating a wide range of metallic and compound targets while supporting both single-layer and multilayer optical film structures.

From reflective coatings and anti-reflection (AR) coatings to optical filters and protective layers, DYPS provides stable and repeatable process control, helping customers rapidly establish mature, production-ready coating recipes.

With its modular design philosophy, DYPS can be equipped with optional heating systems, ion-assisted modules, and process monitoring components to further enhance film quality, process flexibility, and overall system adaptability.

- Plasma Monitoring System for Precise Control of Reactive Sputtering Uniformity

To further improve the controllability of reactive sputtering processes, the DYPS Optical Sputtering Coating System integrates a Plasma Monitoring System, enabling real-time observation of plasma conditions during deposition, including discharge stability, reactive gas influence, and process drift trends.

Through continuous plasma signal feedback, DYPS allows process engineers to precisely regulate reactive sputtering parameters, maintaining film composition and deposition behavior within stable operating windows. This effectively reduces thickness non-uniformity and optical property deviations caused by fluctuations in reactive gas conditions.

This monitoring capability significantly enhances:

- In-plane and batch-to-batch uniformity of reactive sputtered films.

- Process reproducibility during long-term mass production.

- Process stability when switching between different materials and film stacks.

- An Optical Sputtering Platform Designed for Mass Production

Compared to high-end systems focused on pushing extreme process limits, DYPS prioritizes equipment reliability, operational stability, and ease of maintenance.

Its production-oriented design philosophy helps customers reduce process risk, shorten learning curves, and maintain high system uptime in real manufacturing environments.

DYPS is ideally suited for applications including:

- Consumer optical components

- Automotive and industrial optical filters

- Flat optical lenses and protective coatings

- Mid- to high-volume optical coating production lines

-

High-Reproducibility Design: Optimized target configurations and gas flow control minimize process fluctuations. This ensures that optical properties (such as refractive index and transmittance) remain highly consistent across large-scale production batches.

- Dense Film Structure: Leveraging the high kinetic energy of sputtered particles, the system deposits dense, non-porous thin films. This significantly enhances the environmental stability and mechanical durability of the coatings.

-

Dynamic Process Correction: The integrated Plasma Monitoring System (PMS) detects discharge states and reactive gas fluctuations in real-time, effectively suppressing the "process drift" commonly found in reactive sputtering.

- Enhanced Uniformity: Precise regulation of reactive gas flow via signal feedback ensures superior in-plane uniformity across large areas, effectively reducing defect rates.

- Versatile Multi-Target Design: The chamber supports rapid switching between various metallic and compound targets, providing the flexibility to design multilayer structures such as Anti-Reflection (AR), optical filters, and metallic reflective coatings.

- Functional Add-ons: Depending on specific product requirements, the system can be equipped with Ion Sources or heating modules to further strengthen film adhesion and performance on various substrates.

- Production-Oriented Logic: The system is engineered to simplify operational workflows and shorten the learning curve. Designed with maintenance accessibility in mind, it ensures high equipment uptime to meet the demands of 24/7 mass production environments.

DYPS (Dah Young Precision Sputtering System)

Positioning: A stability-driven, mass-production optical sputtering platform. It is specifically engineered for optical coating applications requiring high consistency, 24/7 continuous operation, and controllable yields.

1. Consumer Optics

DYPS is ideal for high-volume production of consumer optical components, perfectly balancing film quality with manufacturing efficiency.

Key Applications:

- Optical filters for smartphones and tablets.

- AR (Anti-Reflective) coatings for camera lenses.

- Display cover glass and optical protective films.

- Optical components for smart wearables.

※ Core Requirements: High batch-to-batch consistency, process stability, and cost optimization.

2. Automotive & Industrial Optics

In the automotive and industrial sectors, optical coatings demand extreme reliability and environmental durability. DYPS excels at providing long-term production stability for these rigorous environments.

Key Applications:

- Automotive optical filters (IR Cut / Bandpass filters).

- Optical components for ADAS cameras and sensor modules.

- Optical filters for industrial vision systems.

- Protective and functional optical coatings for sensors.

※ Core Requirements: High durability, process reproducibility, and long-term production stability.

3. Optical Filters & Functional Films

Equipped with advanced reactive sputtering control and plasma monitoring systems, DYPS enables the stable mass production of complex optical film stacks.

Key Applications:

- Anti-Reflective (AR) coatings.

- Reflective and enhanced-reflection coatings.

- Visible light and Infrared (IR) filters.

- Functional protective and wear-resistant optical films.

※ Core Requirements: Superior thickness uniformity, spectral stability, and high process repeatability.

4. Flat Optics & Volume Optics

DYPS provides a mature and reliable solution for high-volume optical applications focused on flat or low-curvature substrates.

Key Applications:

- Flat optical lenses.

- Optical cover glass.

- Industrial optical windows.

- Protective films for optical modules.

※ Core Requirements: High equipment uptime (utilization), ease of maintenance, and process stability.