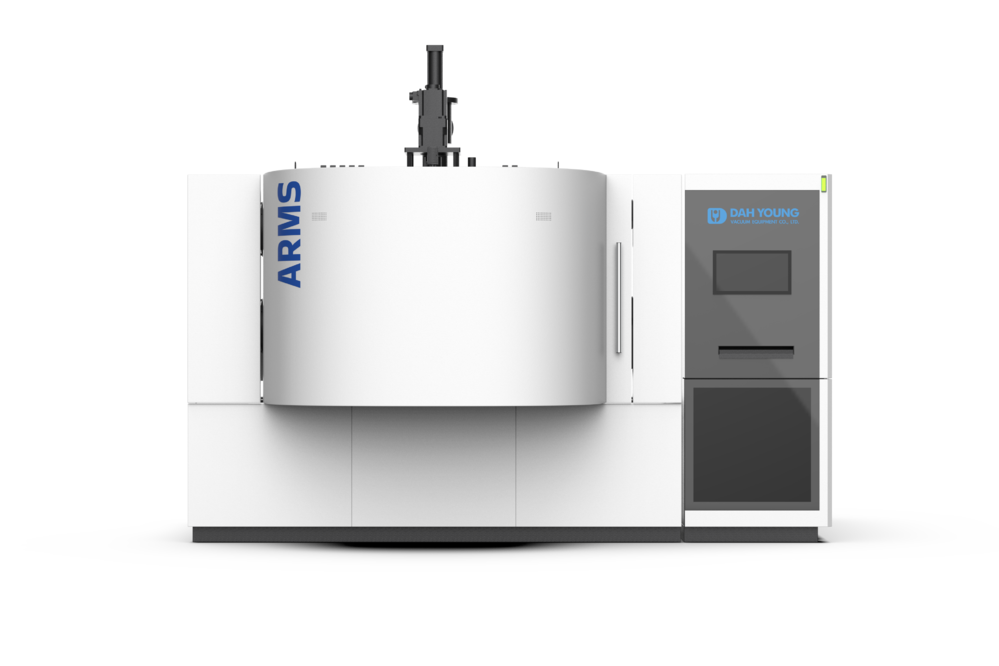

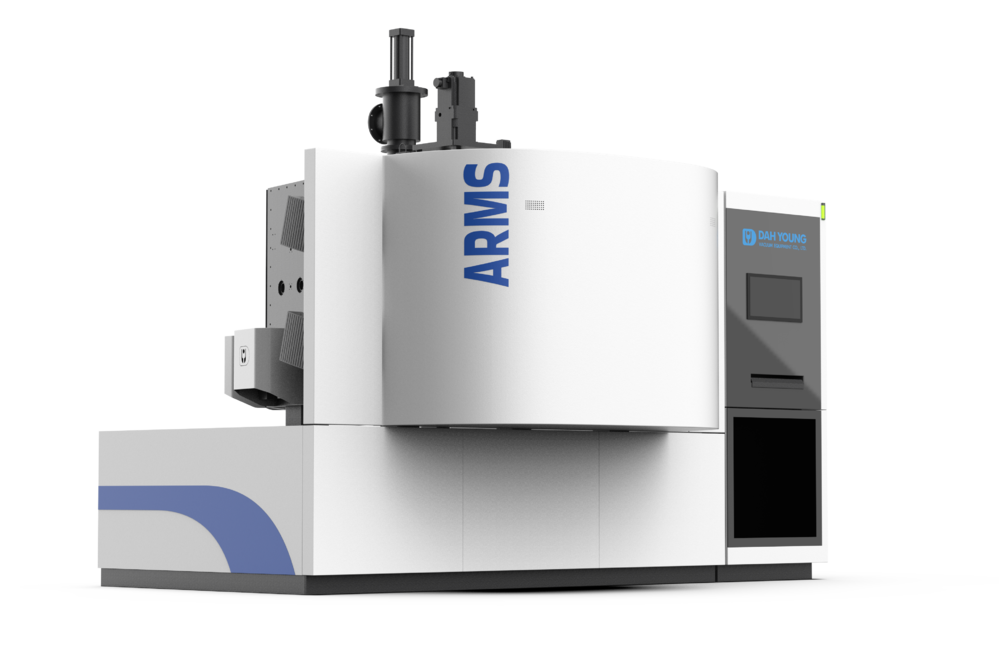

ARMS Coating Machine

- An Innovative Sputtering Solution Engineered for Advanced Optical Coatings

Building upon decades of engineering expertise in optical evaporation systems, Dah Young Vacuum’s R&D team has independently developed ARMS (Activated Reactive Magnetron Sputtering)—a high-precision optical sputtering system.

ARMS successfully introduces magnetron sputtering technology into advanced optical thin-film manufacturing, specifically engineered for applications demanding exceptional film quality, long-term process stability, and outstanding coating uniformity.

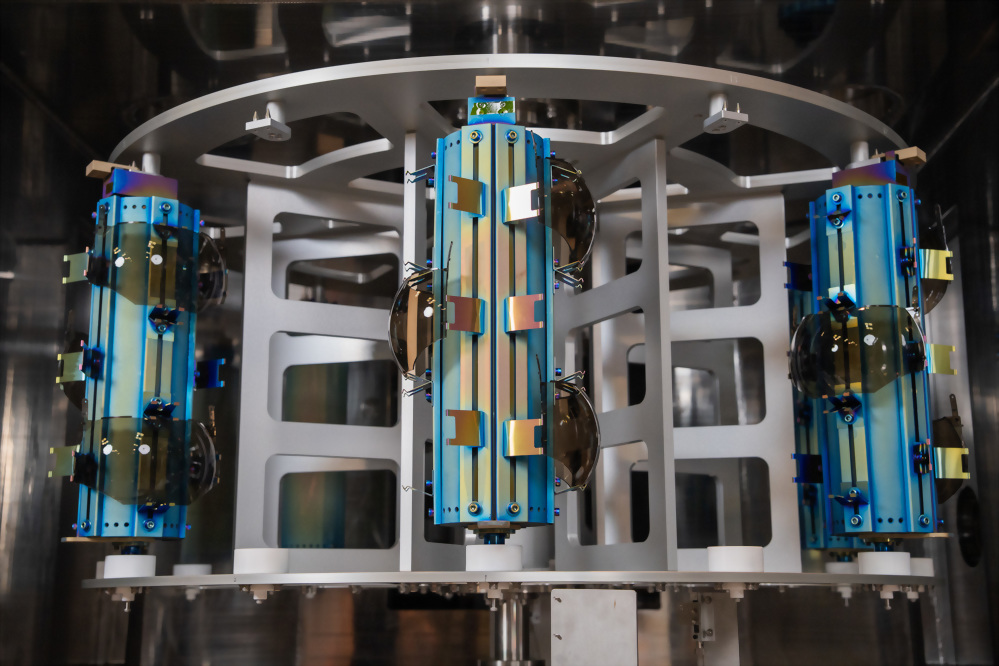

- Core Technology | Separated Activated Reactive Sputtering × High-Speed Rotating Chamber Design

ARMS features an innovative high-speed rotating chamber architecture that physically separates the metal sputtering zone from the reactive plasma zone. During deposition, substrates rapidly shuttle between these two regions, enabling fast and precise alternation between metallic and oxide layers.

This design effectively overcomes the target poisoning issues commonly encountered in conventional reactive sputtering, preventing deposition rate loss and unstable glow discharge that can degrade film quality. As a result, ARMS delivers long-term process stability while maintaining both high deposition rates and superior optical film performance.

- Three Key Process Advantages | Designed for Precision Optics

- Low-Temperature Sputtering Capability - Ideal for temperature-sensitive substrates, meeting the stringent requirements of advanced optical components and next-generation sensing devices.

- High-Efficiency ICP (Inductively Coupled Plasma) Source - Enhances the dissociation and activation efficiency of reactive gases, ensuring dense film structures and stable optical properties.

- Low-Particle Generation Design - Minimizes particle formation during processing, enabling highly uniform coatings with exceptional surface cleanliness for optical applications.

- From Flat to Curved Surfaces | Full Control of Optical Coating Uniformity

With its separated target zone and activated plasma zone, ARMS allows independent introduction of inert gases and activated reactive gases. This significantly reduces target interference from reactive species, enhancing overall sputtering stability and large-area coating uniformity.

Leveraging the inherently high kinetic energy and excellent step-coverage characteristics of sputtering processes, ARMS consistently delivers uniform, stable, and repeatable optical coatings, even on non-planar and complex 3D curved substrates.

- Applications | Meeting the Demands of Next-Generation Advanced Optics

ARMS is ideally suited for optical applications requiring high geometric precision, including:

- Automotive lenses and IR cut filters for autonomous driving systems

- 3D convex optical components for AR / VR / MR devices

- Advanced optical filters with highly consistent, multi-layer structures

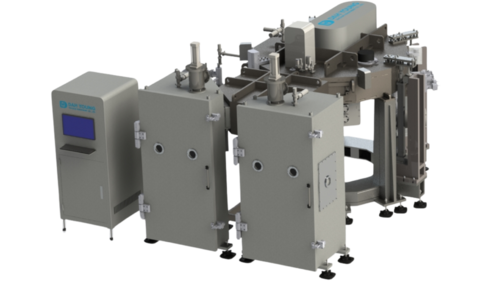

- Flexible Architecture × Advanced Multilayer Stacking Capability

ARMS integrates the high-density advantages of sputtering into optical coating processes, enabling the design of Super Lattice multilayer structures exceeding 50 layers.

The chamber supports multiple target positions and flexible single- or dual-target configurations. Pre-mixed process gases can be introduced to enhance dissociation and activation efficiency, further overcoming the limitations of reactive sputtering.

This architecture fully achieves the ultimate goal of high deposition rate, superior film quality, and exceptional process stability.

- Key Features

- Separated Activated Reactive Sputtering

- The metal sputtering zone and the reactive plasma zone are physically isolated, fundamentally eliminating target poisoning issues commonly encountered in conventional reactive sputtering processes.

- High-Speed Rotating Chamber Design

- Substrates rapidly shuttle between the two zones, enabling fast alternation of metal and oxide layers while achieving both high deposition rates and long-term process stability.

- Three Key Process Advantages

- Low-Temperature Sputtering

- High-Efficiency ICP (Inductively Coupled Plasma)

- Low-Particle Process

Suitable for temperature-sensitive substrates, ideal for advanced sensing devices and high-end optical materials.

Enhances gas dissociation and reaction efficiency, ensuring dense films with stable and consistent optical properties.

Effectively suppresses particle generation, improving film cleanliness and large-area coating uniformity.

- Superior Film Control Capability

- Uniform Coating on 3D Curved Surfaces

- High-energy sputtering combined with excellent step coverage maintains outstanding uniformity even on curved and complex substrates.

- Over 50-Layer Multilayer Stacking

- Supports Super Lattice structures to meet the demands of advanced optical design.

- Highly Flexible Configuration

- Multiple target positions with single- or dual-target designs, allowing flexible process gas mixing and activation control.

- Industry Applications

Developed by Dah Young Vacuum, ARMS (Activated Reactive Magnetron Sputtering) is engineered for advanced optical coatings that demand the highest levels of precision, stability, and consistency.

With its unique separated activated reactive design and low-temperature process capability, ARMS has been successfully implemented across the following key industries:

As the largest market for precision optical components, ARMS delivers both high throughput and exceptional film quality:

-

3D Sensing & Recognition: Narrow bandpass filters for Face ID dot projectors and LiDAR receivers in smartphones.

-

Hidden Sensors: High-transmittance optical sensing films for under-display ambient light sensors (ALS).

-

High-Hardness Protection: Hard, anti-reflective (AR) or color-enhancing coatings for sapphire glass lens covers.

Meeting the stringent safety and durability standards of autonomous driving and smart cockpit systems:

-

Autonomous Driving Core: Highly consistent LiDAR narrow bandpass filters to effectively suppress ambient noise.

-

Imaging Systems: Automotive camera modules and IR cut filters for autonomous vehicles.

-

Information Display Technologies: Precision multilayer coatings on HUD windshields and reflective optics.

-

Driver Monitoring: Infrared optical components for driver monitoring systems (DMS) and fatigue detection.

Designed to overcome the challenges of complex optical paths in next-generation display technologies:

-

3D Convex Optical Components: High-difficulty coating processes for non-planar lenses used in AR / VR / MR devices.

-

High-Precision Optical Filters: Advanced multilayer filters requiring exceptional uniformity to enhance immersive visual performance.

Leveraging ARMS’ low-temperature sputtering and superior uniformity:

-

Wafer-Level Packaging: Direct precision optical coating on CMOS image sensor (CIS) wafers.

-

MEMS Applications: Specialized high-reflectivity coatings for micro-projectors and scanning mirror systems.

Utilizing the spectral selectivity of Super Lattice structures exceeding 50 layers:

-

Medical Diagnostics: Precision beam-splitting optics for PCR systems and biochemical analyzers.

-

Advanced Microscopy: Fluorescence microscope filters with deep blocking performance and high transmission.

-

Environmental Monitoring: Narrowband sensing filters for detecting specific wavelengths in water and gas analysis.

Addressing signal transmission requirements under extreme environments:

-

Laser Communication: High-durability, high-reflectivity mirrors and filters for inter-satellite laser communication in low Earth orbit (LEO).

-

Protective Coatings: Long-term protection for optical components operating under extreme radiation and temperature fluctuations in space.

- Why Choose ARMS?

-

High Deposition Rate with Superior Film Quality: Eliminates target poisoning while achieving both productivity and dense film structures.

-

Exceptional Control over Curved Surfaces: Outstanding step coverage ensures uniform coatings from flat substrates to complex 3D geometries.

-

Ultra-Low Particle Generation: Guarantees the highest level of cleanliness for every optical component.