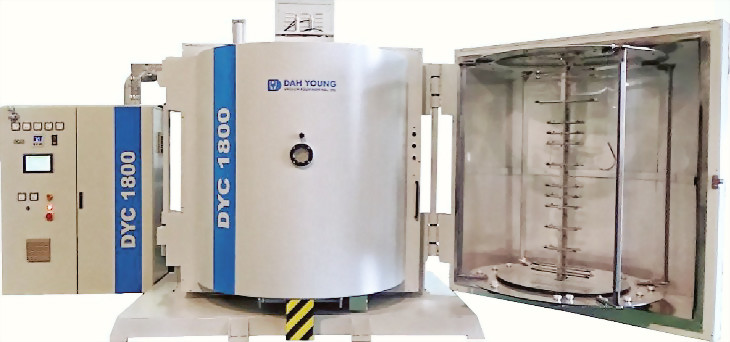

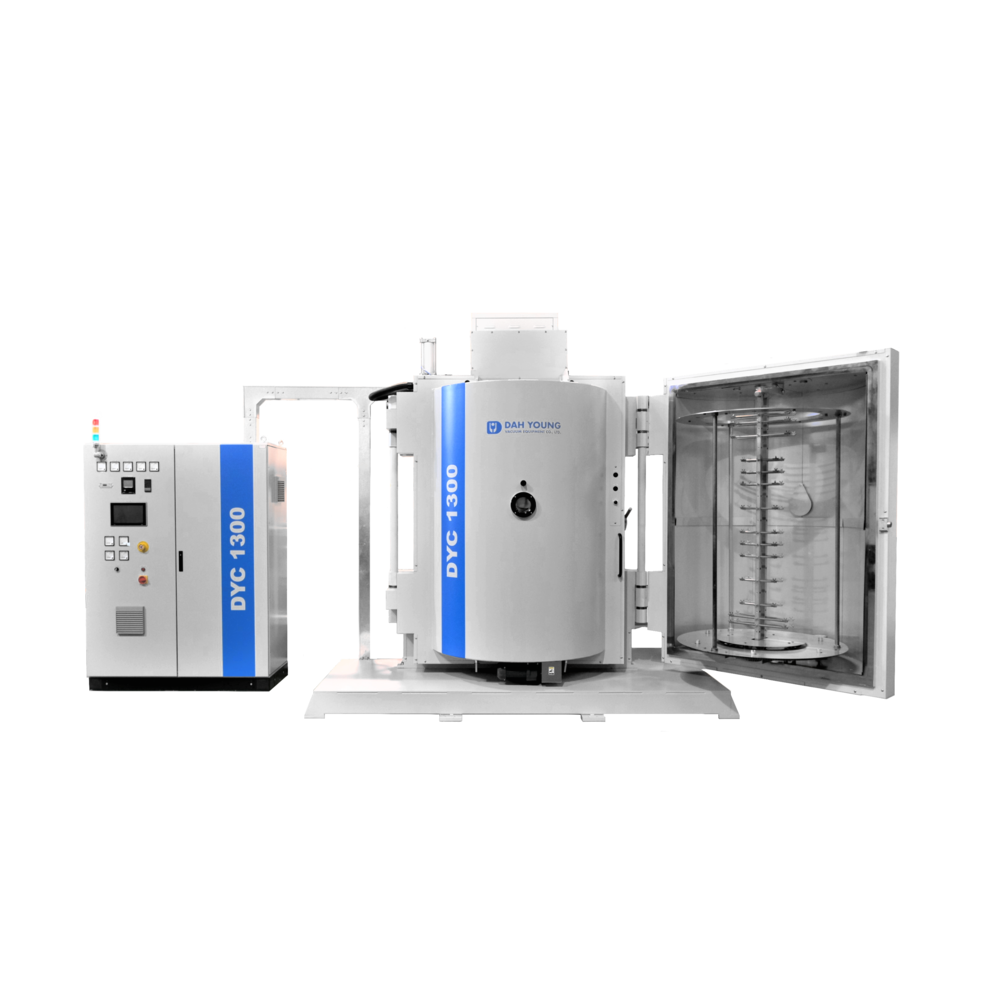

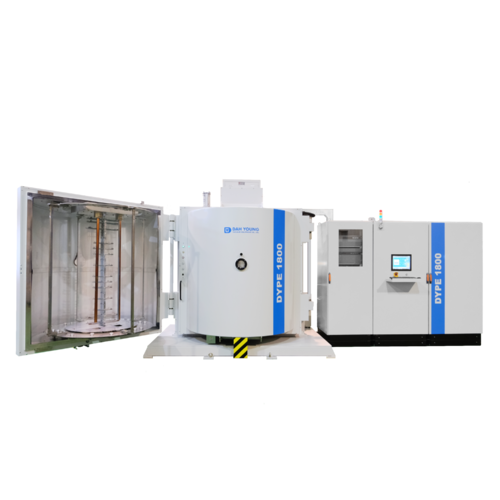

Evaporation Coating Machine

Model :

DYC

DAH YOUNG's DYC-BSD vertical double door vacuum coater is used for the traditional decorative coating process on toys, trinkets,jewelry, Christmas crafts, tableware, etc.

With the fast pace of living standards pertaining to technology demands, the conventional surface coating technology has expanded from the decorative market to a functional market while still decorative appearance for Electromagnetic Interference (EMI) shielding and Non-Conductive Vacuum Metallization (NCVM) to prevent signal interference on 3C products, mobile phones, laptops, etc.

To meet these functional coating market demands, DAH YOUNG developed te DYC-NCVM and DYC-ESP coaters.

- High Productivity, High Quality.

- Reliable Color Effect.

- Special 3D Turning Function.

- Special 3D Evaporation Coating Function.

- Touch Screen Controlled and PLC.

- NEC( National Electrical Code) Qualified.

- One Touch Auto Control.