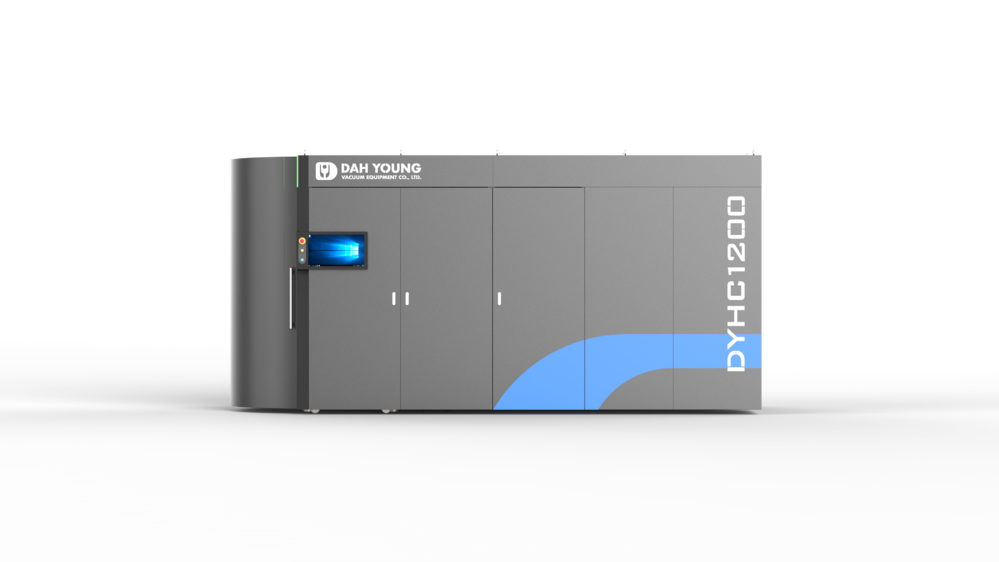

DYHC Coating Machine

- HiPIMS, DLC, CT: Three Hard Coating Systems for Diverse Surface Enhancement

As performance requirements for materials continue to increase across industries, advanced surface treatment has become key to improving product longevity and reliability. The DYHC series includes three high-performance hard coating systems: CT (Cathodic Arc for TiN/TiAlN nitrides), DLC (Diamond-Like Carbon), and HiPIMS (High Power Impulse Magnetron Sputtering). These technologies deposit functional coatings with high hardness, excellent wear resistance, corrosion resistance, and low friction, making them ideal for applications in tooling, mechanical parts, automotive components, electronics, and semiconductors.

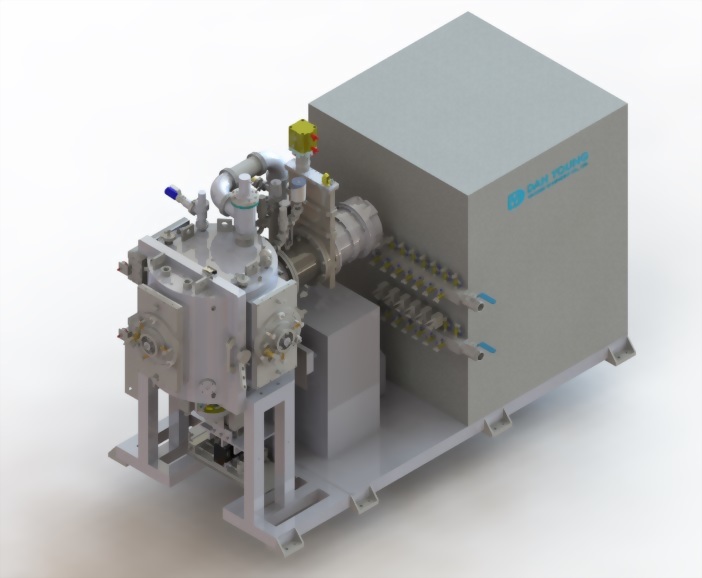

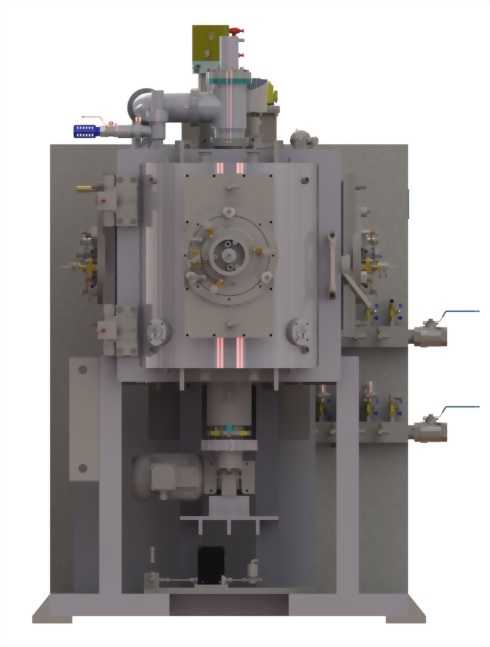

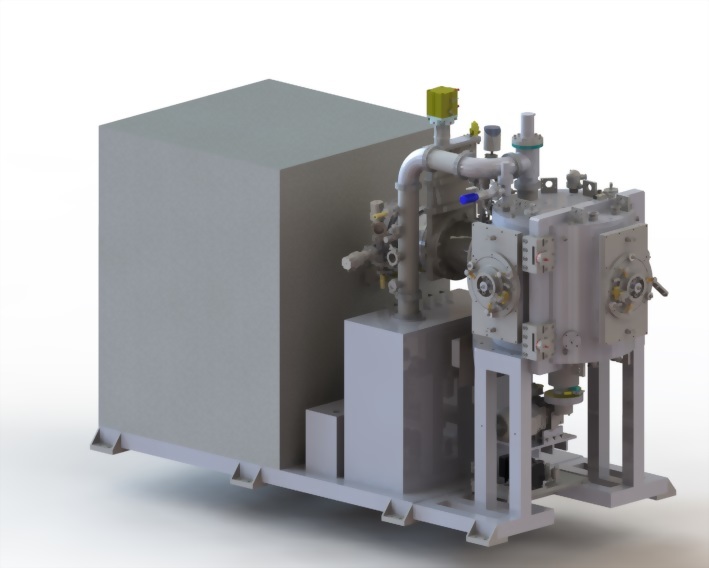

- Intelligent Control and Modular Design for Consistent, High-Density Coatings

DYHC systems feature one-touch production, precision process control, and modular system configuration, ensuring consistent and high-quality coating results. The CT and DLC series adopt Cathodic Arc Deposition (CAD) and can be equipped with a magnetic filtration system to minimize particles and enhance coating density and adhesion. HiPIMS generates instantaneous high current through a high-power pulse generator with a low duty cycle (<10%) of tens of microseconds, producing high power density at the kW/cm² level. This high-energy pulse excitation significantly increases the ionization yield during the sputtering process, resulting in highly ionized atoms in the deposition process and the formation of very high coating density on the substrate. This technology effectively improves the physical properties of the coating, such as nanocrystalline structure, high coating density, high hardness, excellent wear resistance, and extremely low surface roughness, further expanding the potential use of HiPIMS in high-end applications.

- Customized Coating Solutions to Enhance the Performance of Tools, Components, and Electronic Devices

DYHC provides targeted coating solutions tailored to the performance needs of various sectors:

■ The CT series is optimized for cutting tools and molds, offering robust TiN/TiAlN nitride coatings that withstand high wear and thermal loads.

■ The DLC series is designed for low-friction and high-wear applications, such as mechanical parts and semiconductor testing components, offering a combination of hardness and lubricity that reduces wear and energy loss.

■ The HiPIMS series supports high-end electronics applications, producing ultra-smooth, high-density films with exceptional adhesion and microstructural control.

As industries like 5G, electric vehicles, semiconductors, and smart manufacturing continue to evolve, DYHC’s advanced hard coating systems enable customers to enhance component performance, reduce maintenance costs, and maintain a competitive edge.

- Common Features (CT / DLC / HiPIMS)

- Fully automated control system (IPC & PLC): Ensures process automation and stable, repeatable production.

- Composite multilayer coating capability: Supports the deposition of complex, multi-layered functional coatings.

- Batch-type chamber with customized planetary rotation system: Accommodates a wide range of workpiece shapes and sizes for high-volume production.

- Modular coating technology architecture: Allows flexible integration of additional coating modules to meet evolving customer needs.

- EU CE compliance (optional): Meets international safety and technical standards for global market readiness.

- CT / DLC Series – Exclusive Features

- Optional magnetic filtration system: Effectively filters arc-generated particles to enhance film density and uniformity.

- Coating material options:

- Multinary nitrides: TiN, TiAlN, TiCrN, TiSiN, AlCrN, AlTiSiN, AlCrSiN, TiCrSiN

- DLC (Diamond-Like Carbon), Me is a doping metal element: a-C, a-C:Me, ta-C

- HiPIMS Series – Exclusive Features

- High ionization rate and low surface roughness coating capability: ideal for ultra-dense nanostructured films and micro scale substrate.

- Coating material options:

- Binary / multinary nitrides: TiN, CrN, AlCrN, AlCrXN

- Binary oxides: TiO₂, Cr₂O₃

- Binary carbides: TiC, CrC

-

CT & DLC

Engineering:

- Cutting Tools: End Mills, Special Machining Tools

- Mechanical Components: Micro Hinges, Micro Capacitor Winding Fixtures

- Precision Molds: Optical Molds, Powder Metallurgy Molds, Forming Molds

- Automotive Components: Shock Absorbers, Gear Discs

-

HiPIMS

Engineering:

- Micro Tools: Micro Drills

- Automotive Components: Shock Absorbers, Plungers, Piston Rings

Semiconductors:- Packaging and Testing: Chip Bonding Machine Molds, Inspection Fixtures

Medical:- Biotechnology: Disposable Blades for Pathology Slicing Machines