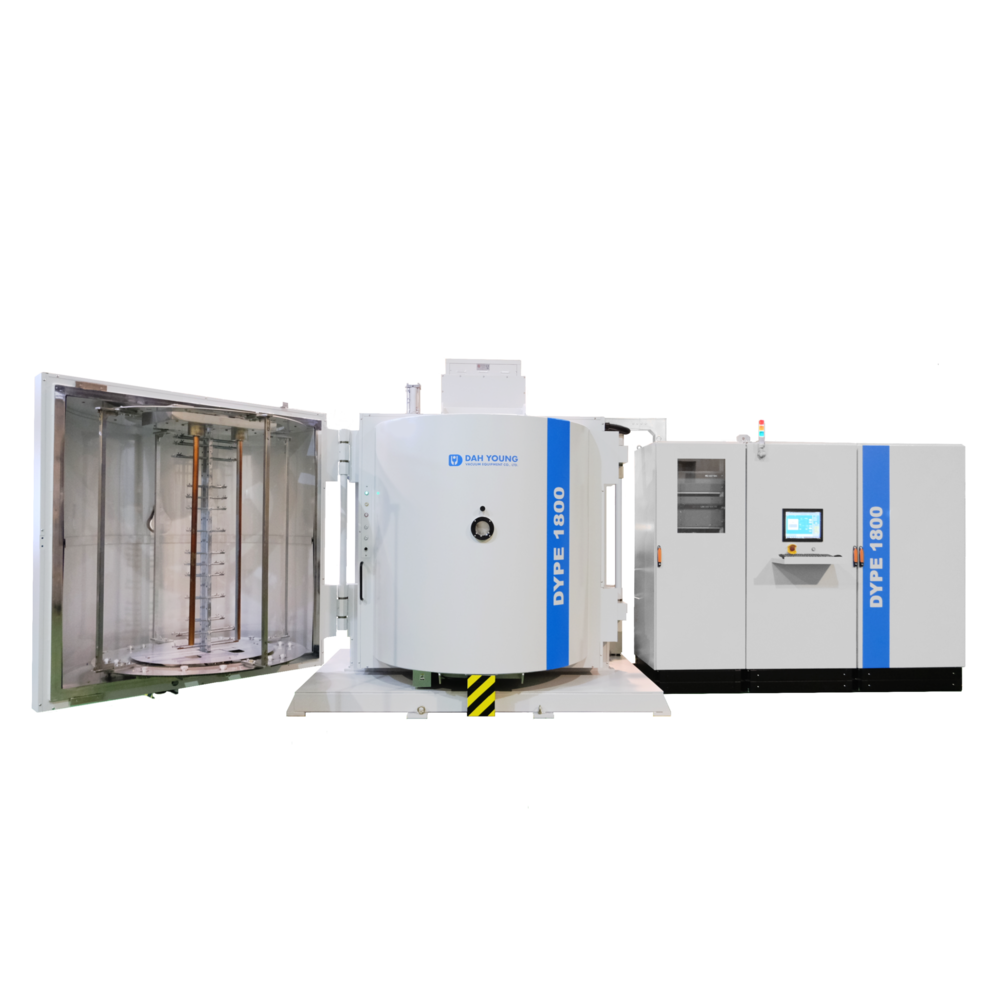

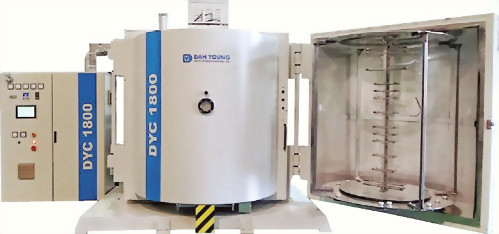

Hybrid Coating Machine

|

To keep up with the everchanging market demands along with environmental awareness, DAH YOUNG successfully developed the new DYPE-Economy Hybrid Coater. The DYPE incorporates the PECVD process of base and top coating the substrate in traditional atmospheric apray booths into the vacuum chamber with the PVD process. This not only enhances the end product by less handing, but it improves the coating layers and adhesion by applying the base coat, PVD and top coat in a single vacuum operation. also increasing productivity and eliminating the need and floor space for eco-unfriendly atmospheric spray booths.

|

Features:

- Flawless, efficient operation: Rapid cycle coating for increased production pace and ultimate production cycle time.

- Optimum Pumping System: Streamline vacuum piping system equipped with high-performance pumps.

- Exterior Valve Design: To minimize interior vacuum contaminates within the chamber pumping efficiency

- Fully Automated Control (IPC & PLC) : Multiple recipes storage and run history recording space with remote control access and monitoring.

Environment Performance Test:

Car light reflector,bezels and trinkets.